Original Equipment Manufacturers (OEMs) nowadays partner up with solution providers that offer industry expertise, experience and holistic assistance from early prototyping to production, post-production and eventually product decline. Those solution providers are called Electronics Manufacturing Services.

Unlike OEMs, they do not own rights to the product. They, manufacture, test, deliver and often provide aftermarket maintenance for electronic parts and assemblies. EMS are steady experts leading you not only through the production process which can give your product an advantage over your competitors, but they are also valuable business partners providing support and maintenance through product`s life-cycle. For example EMS can act as advisors for companies on the parts that have a better lead time and lower cost.

Today, electrical components (such as batteries) are becoming lighter and smaller. Modern electronics should take up less space and fit into bold, new projects. Electronics manufacturing services companies need to go beyond simply offering manufacturing services.

EMS-global tendencies

Due to rising demand for consumer and automotive electronics, rapid expansion of mobile devices and focus on core competences and advanced skills in companies which seek experts in a specific field, EMS have become an important part of many businesses in the world. The demand for electronic components and outsourcing of manufacturing services is rising dramatically. Business forecasts estimate 7.5% annual growth of this industry between 2018 and 2024. The question is what we can expect from EMS companies?

EMS range of tasks

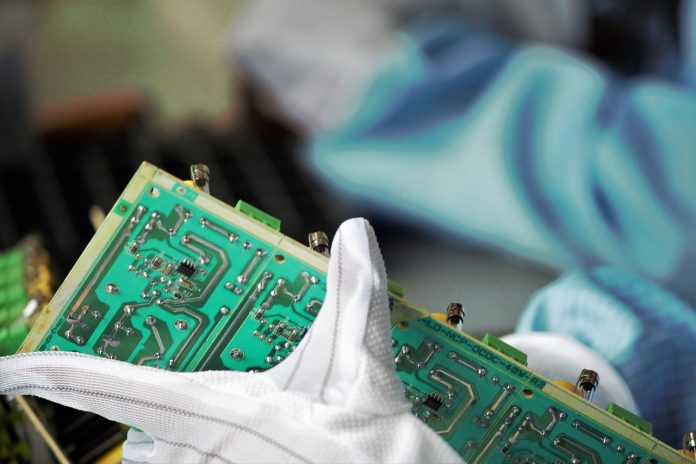

The range of EMS depends on the supplier. Some vendors may offer from one to each of these services: prototyping, PCB assembly, cable assembly, electromechanical assembly, contract design, testing or post-production services.

Some of the services are standard and common, while others offer more niche or specialized help. A medical company for example, might need a specific certification that a printing company does not. Medical, Transportation or safe&security companies are sensitive about the quality of the material used in the manufacturing process.

Some EMS are simply looking to print bare boards in huge volumes. Others offer complex, creative solutions in smaller volumes and assist with several steps of the supply chain. A great deal of EMS tend to provide customized services. The customer very often extends the order from a simple product e.g. a circuit board through a value-added assembly like cables, wires or box to automated inspection and programming.

Applications of EMS:

EMS have application in a wide-array of industries-from government agencies (aerospace and defence), consumer electronics (PCs, smartphones, tablets), robotics and automation, electronic components (connectors, semiconductors, microchips) to health care (digital health market).

As they often become long-lasting partners for OEMs, they focus on best quality of their service and do their best to make the business successful.